When EV batteries face the risk of overheating, generator rooms struggle with both heat and noise, or defence vehicles operate in extreme conditions—basic insulation simply falls short. Today’s industrial environments demand smarter protection. That’s where composite insulation makes the difference.

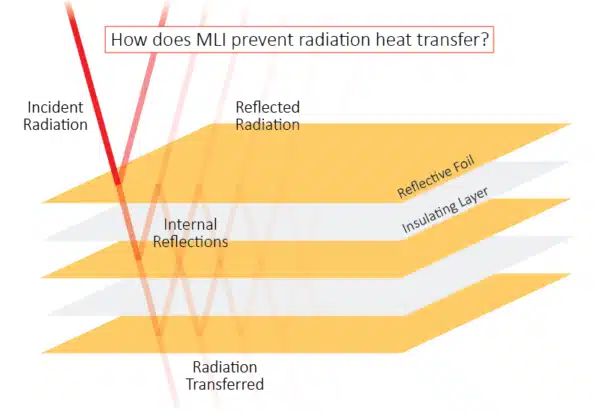

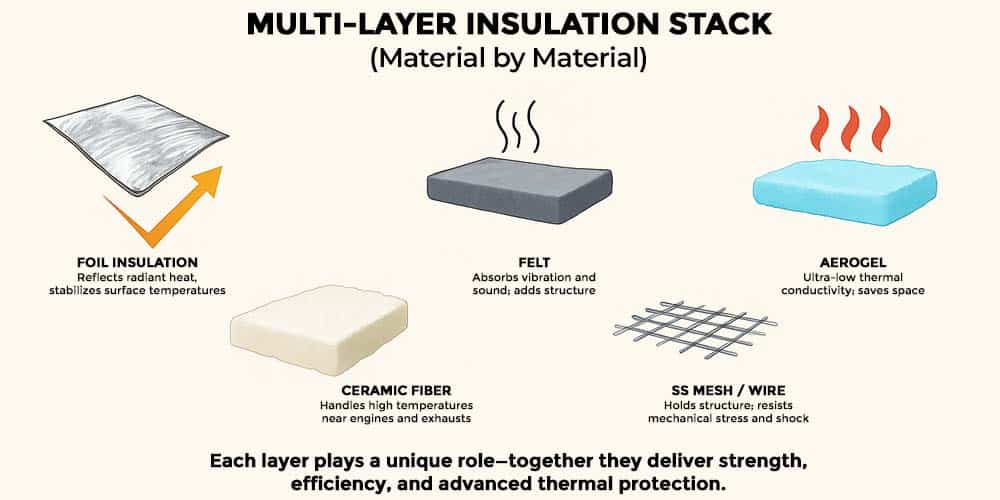

Unlike single-layer solutions, composite insulation combines multiple engineered materials—like foil, felt, and aerogel—to deliver superior thermal, acoustic, and mechanical performance.

At PBM Insulations, we don’t just manufacture—we engineer. With over 23 years of expertise, we design precision-engineered insulation that are tested, validated, and tailored for EVs, power systems, defense equipment, and more.

Discover how multi-layer insulation systems are reshaping the way industries tackle heat, vibration, and reliability—layer by layer.

Why Single-Layer Insulation Is No Longer Enough

Single-layer insulation may provide basic protection, but modern applications demand more. From EVs to defense systems, performance hinges on advanced materials that manage heat, sound, and stress. That’s why multi-layer insulation has become the new industry standard.

From Basic to Composite

Traditional single-layer insulation serves one purpose—blocking heat or sound. But in industries like automotive, defense, and power generation, that’s rarely enough.

Composite insulation—also referred as multi-layer insulation—goes further. By stacking materials like foil, felt, aerogel, andglass wool, PBM creates systems where each layer handles a specific threat. It’s not just insulation. It’s engineering.

Designed for Real-World Stress

Composite insulation is especially critical in:

- EV battery insulation, where thermal runaway can endanger safety.

- Generator enclosures, where heat and noise must be managed in tight spaces.

- Military vehicles, which need fire-resistant, shock-absorbing solutions.

Each layer adds a new line of defense—together creating high-performance thermal barriers that outperform any single material.

How PBM Engineers Composite Insulation Solutions

At PBM, every composite solution is designed using advanced engineering tools and validated in-house. From digital simulations to lab testing, we ensure each layer works together seamlessly to deliver unmatched thermal performance, durability, and precision tailored to your specific application.

Tools That Make the Stack Work

At PBM, insulation isn’t guessed—it’s simulated, modeled, and tested.

Using SolidWorks thermal simulation, Prolog by Scannex, and Simu-Therm, PBM engineers evaluate:

- Heat flow under extreme stress

- Material response to vibration and shrinkage

- Optimal stack-up thickness and composition

Every product is custom-designed using data, not assumptions. That’s stack-up insulation design at its smartest.

Lab-Backed Validation, Every Time

PBM’s in-house insulation testing lab ensures every composite insulation solution works before it leaves the factory.

- Muffle furnaces test how materials handle high-temperature exposure.

- Oven-based analysis checks for moisture retention and solid content.

- Shrinkage and LOI tests simulate operational aging.

With simulation-led design and rigorous lab validation, PBM delivers insulation solutions that don’t just meet standards—they set them. That’s the confidence we bring to every layer we engineer.

Composite Insulation in Action: Where Every Layer Counts

Composite insulation isn’t theory—it’s tested performance in the field. From electric vehicles to generators and defense systems, PBM’s multi-layer solutions are built to excel under pressure, heat, vibration, and noise—where it truly matters.

EV Battery Insulation

Electric vehicles generate intense heat, especially around battery packs. To ensure safety, performance, and efficiency, PBM designs specialized stack-ups—like aerogel, Synthalon felt, and aluminium foil—that offer advanced thermal resistance without adding weight or compromising on space.

- Lightweight thermal insulation

- High resistance to thermal propagation

- Protection during extreme ambient shifts

It’s how PBM helps OEMs tackle thermal runaway prevention—safely and efficiently.

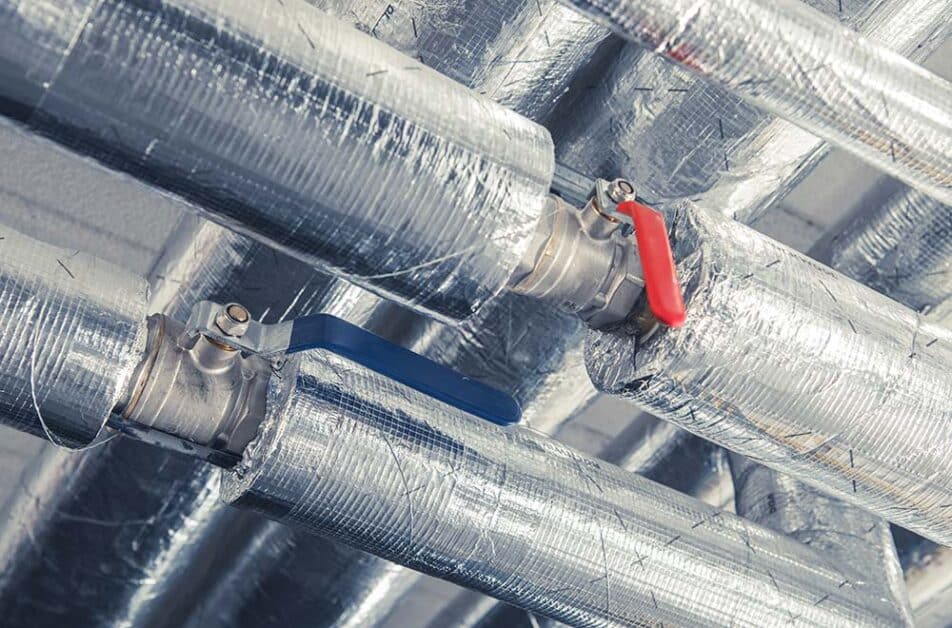

Thermal Insulation for Generators

Generator housings face two enemies: heat and noise. PBM’s solution? A layered design using stitched acoustic mats, foil-laminated slabs, andSS mesh. By layering stitched acoustic mats, aluminium foil slabs, and SS wool, we deliver durable thermal and acoustic protection—ideal for industrial and power generation environments under constant operational stres

This creates:

- Acoustic and thermal shielding

- Fire resistance and moisture control

- Extended durability in high-vibration zones

Defense-Grade Insulation

PBM’s defense-grade insulation materials power military performance. Whether it’s an armored vehicle’s exhaust system or engine bay, our composite designs:

- Withstand up to 1000°C

- Resist fire and abrasion

- Reduce infrared signature for stealth

PBM’s flexible jackets and ceramic wraps are trusted by leading defense integrators.

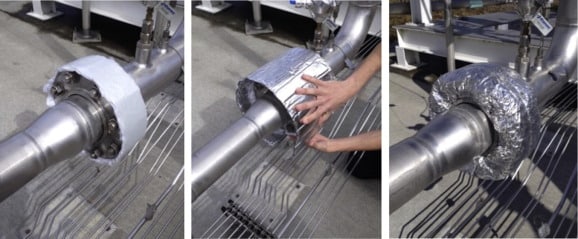

PBM’s Process: From Idea to Installation

At PBM, delivering precision insulation solutions isn’t just about the product—it’s about the process. We manage everything in-house, from first inquiry to final dispatch, ensuring complete control, quality, and speed. PBM simplifies complexity with a well-defined, tested approach.

How the Process Works

- RFQ and NDA

- Application-specific design and simulation

- Custom stack-up engineering using SolidWorks, Prolog, and Simu-Therm

- Prototyping and detailed cost submission

- Lab validation for LOI, shrinkage, and moisture performance

- Scaled manufacturing with zero-PPM quality checks

- Final dispatch with full documentation

PBM is certified by ISO, IATF, and Ecovadis, and delivers end-to-end solutions with accountability at every step. No outsourcing, no guesswork—just insulation that’s engineered to perform.

Are you in search for a partner for performance. We’re ready to build with you.

What’s Next in Insulation Technology

PBM’s R&D team is actively pushing the boundaries of what composite insulation can do. Our focus is on innovation that delivers smarter, lighter, and more adaptable protection across industries.

Key developments underway:

- Phase-change materials. These enables temperature regulation by absorbing and releasing heat.

- Gradient-density layering. Optimize weight and thermal performance across different zones within a single system

- Adaptive stack-ups. Custom configurations that respond to varying heat, vibration, or spatial constraints

With a 25% annual growth rate and increasing demand in EV and defense insulation, PBM is investing heavily in future-ready materials and design strategies.

We’re not reacting to industry shifts—we’re anticipating them. For OEMs and system integrators seeking performance-driven, scalable insulation, PBM is building what’s next.

Conclusion

In today’s high-performance industries, insulation is no longer a single-layer fix—it’s a multi-layer engineering solution. At PBM Insulations, we design and deliver composite insulation systems that combine thermal efficiency, acoustic control, and mechanical durability.

From EV battery insulation to defense-grade thermal barriers, every solution is backed by simulation, lab testing, and zero-PPM quality. With in-house capabilities and future-ready R&D, PBM is the trusted OEM insulation partner for industries that demand performance under pressure.

Have a thermal challenge that needs a smarter solution? Let PBM custom-engineer a multi-layer insulation system built to perform—get in touch today.