Imagine a battery pack inside an electric vehicle on a peak-summer day in Delhi traffic. The temperature soars past 45°C, and inside the pack, cells are heating up rapidly. Without composite insulation to contain the heat, a thin single-layer sheet struggles to cope, and the risk of thermal runaway becomes real.

This is not just a distant concern. According to IDTechEx, the objective is to provide a comprehensive review of thermal management systems (TMSs) in electric vehicle (EV) battery packs. This will give an emphasis on strategies that boost performance, enhance safety, and ensure long-term reliability.

. Defence vehicles, boilers, and power systems face similar risks, from fire hazards to efficiency loss.

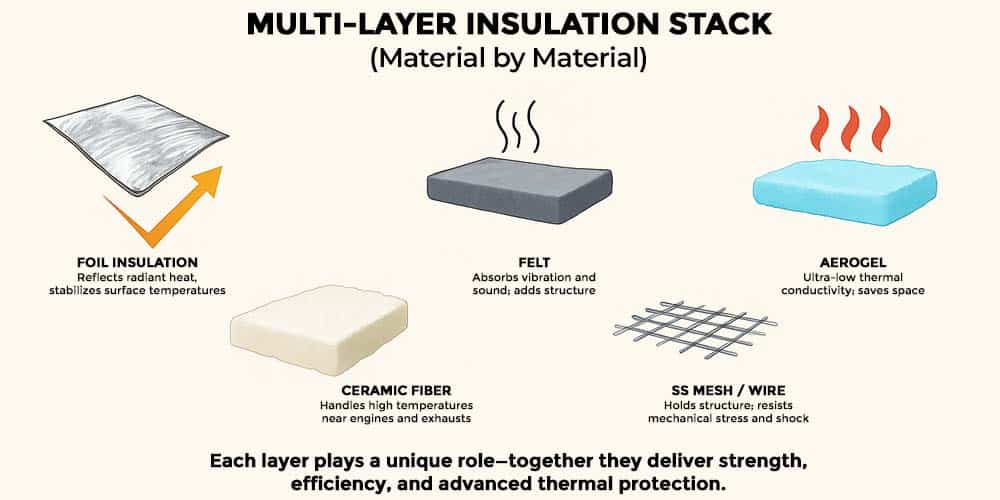

Composite insulation has emerged as the answer. By combining multiple engineered materials into a high-performance stack, it resists heat, absorbs vibration, and ensures long-term durability. This article highlights five real stack-ups from PBM Insulations, engineered for electric mobility, defence systems, industrial boilers, and electrical applications.

PBM, with over three decades of engineering expertise, in-house R&D labs, and partnerships with leading OEMs, positions itself as an insulation architect. The thesis is simple: every layer matters, and the right stack-up delivers performance where it matters most.

Also Read:

Why Multi-Layer Insulation Matters

Insulation has traditionally relied on single materials like glass wool mats or ceramic blankets. These provide basic heat resistance but fall short when exposed to the multi-dimensional stress of modern applications. This is where Multi-layered Insulation steps in.

What composite insulation delivers:

- Thermal conductivity control to manage heat flow effectively

- Acoustic dampening for noise reduction in industrial and automotive environments

- Fire resistance to improve safety in high-risk systems

- Vibration management for durability under continuous load and motion

Why OEMs choose it:

- Higher efficiency and reduced operational losses

- Improved safety across EVs, defence, and industrial platforms

- Compliance with strict global standards

Real-world results:

- In EVs, prevents battery fires and extends driving range

- In defence vehicles, withstands temperatures above 1000°C while lowering infrared signatures

- In boilers, it can cut heat loss and boost operational efficiency by nearly 15%

Multi-layer insulation has moved from being a premium option to becoming the standard in modern engineering.

Stack-Up 1: Aerogel + Felt + Aluminium Foil

Electric vehicles are particularly sensitive to heat management. To protect EV battery packs, PBM develops a triple-layered insulation system focused on thermal safety.

- Aerogel: lightweight, high thermal resistance, up to 600°C

- Synthalon felt: absorbs vibration and adds acoustic protection

- Aluminium foil: creates a fire barrier and prevents moisture ingress

Performance Benefits:

- Prevents thermal runaway in EV battery packs

- Reduces weight, helping improve EV range

- Adds fire safety for passenger protection

- Provides vibration control during constant vehicle motion

| Materials | Temperature Range | Key Benefits | Application |

| Aerogel + Felt + Aluminium Foil | Up to 600°C | Thermal runaway prevention, vibration resistance, fire safety | EV Battery Packs |

This stack-up is trusted by automotive OEMs designing next-generation EVs where weight, safety, and efficiency must coexist.

Stack-Up 2: Ceramic Fiber + SS Wool + Wiremesh

Military platforms operate under extreme stress. To meet defense grade insulation, PBM crafts a triple-layer insulation design built for extreme conditions.

- Ceramic fiber: withstands temperatures above 1000°C

- Stainless steel wool: absorbs vibration and resists heat cycling

- Wiremesh: provides structural reinforcement and abrasion resistance

Performance Benefits:

- Fireproof insulation in armored vehicle exhausts

- Vibration resistance for durability under rugged conditions

- Stealth capability by reducing infrared emissions

- Long-term performance in harsh environments

| Materials | Temperature Range | Key Benefits | Application |

| Ceramic Fiber + SS Wool + Wiremesh | Up to 1000°C | Fireproofing, vibration absorption, stealth advantage | Defence Exhaust Systems |

By integrating ceramic and stainless steel components, PBM delivers insulation systems built to survive battle conditions without compromise.

Stack-Up 3: Stitched Acoustic Mat + Foil-Laminated Slab + SS Mesh

Power systems like generators face a dual challenge: constant heat and continuous noise. PBM’s layered solution manages both.

- Stitched acoustic mats reduce operational noise

- Foil-laminated slabs reflect heat and resist moisture

- SS mesh adds durability against vibration and load stress

Performance Benefits:

- Dual acoustic and thermal protection

- Fire and moisture resistance

- Built to satisfy compliance requirements for heat protection and noise reduction in power generation units.

- Reliable performance under 24×7 load

| Materials | Temperature Range | Key Benefits | Applications |

| Acoustic Mat + Foil Slab + SS Mesh | 500–600°C | Thermal shielding, noise control, moisture barrier | Generator Enclosures |

This insulation stack ensures efficient and safe generator operation in industrial plants and power stations.

Stack-Up 4: Supermat ECR + Aluminium Foil + Synthalon Felt

Boilers operate under relentless high-temperature conditions, making reliable insulation essential. PBM’s design balances durability with operational efficiency.

- Supermat ECR mat offers thermal resistance up to 750°C

- Aluminium foil reflects thermal energy and acts as a moisture barrier

- Synthalon felt absorbs vibration and reduces noise

Performance Benefits:

- Reduces heat loss and improves boiler efficiency

- Enhances operational safety by lowering surface temperature

- Delivers acoustic dampening in noisy boiler environments

- Provides long-lasting durability with reduced maintenance

| Materials | Temperature Range | Key Benefits | Application |

| Supermat ECR + Aluminium Foil + Synthalon Felt | Up to 750°C | Energy efficiency, fire safety, vibration absorption | Boilers and Furnaces |

For manufacturers and power operators, this translates into lower costs and improved safety compliance.

Stack-Up 5: Aerogel + Pyro-thin Mat + Flexible Heat Shield

Electronic control units in EVs and electrical systems require compact yet reliable insulation. PBM delivers with this three-layer stack.

- Aerogel ensures lightweight thermal management

- Engineered for confined spaces, the Pyro-thin mat ensures strong resistance to high temperatures.

- Flexible heat shield allows space optimization without reducing performance

Performance Benefits:

- Prevents overheating of sensitive electronic systems

- Space-efficient and lightweight for compact assemblies

- Eco-friendly material selection

- Stable performance under fluctuating load cycles

| Materials | Temperature Range | Key Benefits | Application |

| Aerogel + Pyro-thin Mat + Flexible Heat Shield | 500–600°C | Compact safety, lightweight insulation | EV and Electrical Control Units |

This stack-up supports modern EV platforms and industrial control systems where space is limited and performance cannot be compromised.

How PBM Engineers Custom Stack-Ups

PBM’s strength lies not just in materials but in process. Each insulation stack is designed and validated through a structured approach.

- RFQ and NDA with the OEM to ensure clarity and confidentiality

- Simulation using SolidWorks, Prolog, and Simu-Therm for thermal behavior and vibration response

- Prototype creation and validation in PBM’s in-house lab using furnaces, ovens, and shrinkage tests

- Manufacturing under ISO, IATF, and Ecovadis certifications, with zero-PPM quality standards

- Final dispatch supported by full documentation and traceability

This end-to-end control reflects PBM’s commitment to engineering trust, not just insulation products. With more than 25 percent annual growth and ongoing R&D in phase-change and adaptive materials, PBM is positioned as a forward-looking partner for OEMs worldwide.

Also Read:

Conclusion

Composite insulation is no longer an option. It is the foundation of safe, efficient, and future-ready design in industries from electric mobility to defence and power generation. Single layers can no longer keep up with modern performance demands.

PBM Insulations has demonstrated expertise, authority, and trustworthiness by delivering proven multi-layer insulation solutions for over three decades. With advanced tools, an in-house testing lab, and partnerships with leading OEMs, PBM creates systems that are not just materials but engineered architectures.

Every layer counts, and every stack is designed to perform under pressure. Looking for precision stack-up insulation for your next platform? Let PBM engineer it layer by layer.

Ready to Future-Proof Your Product with Insulation That Performs?

At PBM Insulations, we engineer thermal and acoustic solutions that power India’s leading OEMs. Whether you’re building the next electric vehicle, optimizing industrial machinery, or looking to enhance sustainability — we’re here to co-create with precision, trust, and performance.

Let’s turn your insulation challenges into engineered solutions.

???? Reach out for a custom consultation

???? Visit us at: www.pbminsulations.com

???? Call us: +91-7310777959

???? Connect with us: LinkedIn | YouTube | Instagram

Join our network for monthly insights on insulation innovation, EV breakthroughs, and industry trends. Subscribe to PBM Insulation Insights today.

“Crafting Quiet Strength Since 1993” | An IATF, ISO & Ecovadis Certified Company | Your OEM Partner in Thermal & Acoustic Innovation